Refining Process

How it works

Step 1: D12 Receives Your Material

Upon arrival of your material for refining, two D12 team members open your package and weigh the contents. If there is a discrepancy between the packing slip and the weight received, then you are contacted before your material is sent onto the next step in the refining process. After the material has been weighed and the amounts confirmed, the data is entered into our computer system to generate a unique job number just for your refining lot.

Step 2: Preparation Before the Sample

Our experienced personnel review each job before it is melted to confirm the necessary and most profitable refining procedure for you. Depending on the type of material the decision could be any one or combination of: incineration, milling, screening, chemical leaching (we can remove & return valuable diamonds for example), smelting, or melting.

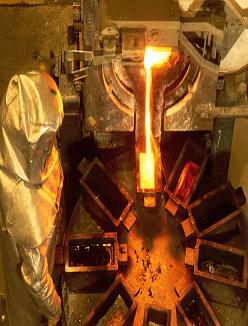

Step 3: Sampling

D12 uses various sampling methods. For precious metal scrap, the material is melted in an induction or gas furnace. Once the metal is molten we use a vacuum-sealed glass tube to remove a small sample of material to test for fine metal content. For materials requiring incineration, a homogeneous powder sample is removed to test for fine metal content. All samples are sent to our in-house laboratory for analysis using the latest technology and most accurate methods to determine the purity.

Step 4: Analyzing

D12 is capable of analyzing the fine metal content to parts per million (PPM), assuring accurate settlements. Depending on the type of material we may use XRF, ICP, or a fire assay to determine the percentage of fine metal contained. The result of the analysis is then entered into our computer system for settlement.

Step 5: Settlement

The settlement is based on the net fine metal contained in the refined material, valued on the daily market prices D12 offers a variety of settlement options from which to choose: check, product exchange, wire transfer, vault account, or credit to account. D12 settles and pays in as little as 2 days, so you receive your money fast.